55-gallon drums are universal containers found across industries and applications worldwide. They offer versatility in storing and transporting various materials, from powders to liquids and solid goods. Industrial 55-gallon drums are designed to tolerate stacking, rough handling, and challenging environmental conditions, all while keeping the contents safe and sealed.

What is a 55 Gallon Drum?

A 55-gallon drum is a cylindrical shipping container for storing and transporting liquids, solids, and other materials. The capacity of 55-gallon drums is equivalent to 208 liters. 55-gallon drums are commonly made of steel and come in plastic, fiber, and stainless steel varieties. The history of the 55-gallon drum dates back to the early 20th century, when drums were made of wood and used for transporting oil. With the oil industry’s rise, the need for a standardized container surpassed the quality of wooden barrels, emerging 55-gallon containers. As industries evolved, the design and materials used for 55-gallon containers changed, with steel becoming the standard due to its durability and robustness. Compared to wood, steel drums offer more resistance to breakage and a more effective seal, providing a safer solution for storing flammable or volatile materials.

What are 55 Gallon Drums Used For?

55-gallon drums, commonly made of steel, plastic, or fiber, serve various purposes across numerous industries. In the industrial sector, they are fundamental for storing and transporting bulk liquids such as chemicals, solvents, oils, and paint, ensuring safe containment and ease of shipment. These drums are often repurposed for rainwater collection, acting as rain barrels to store water for gardening or emergency use. In waste management, 55-gallon drums provide a robust solution for containing hazardous and non-hazardous waste materials. When sealed, 55-gallon drums can build a floating dock, creating buoyant platforms floating 20 inches above water level.

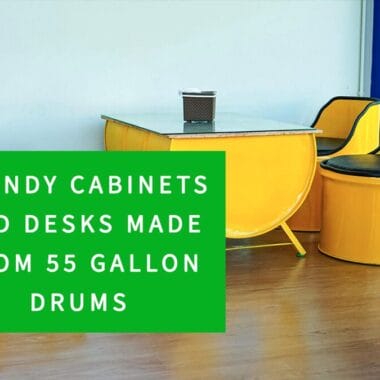

Beyond their traditional roles, these 55-gallon drums have been repurposed and transformed into furniture, art pieces, and storage units. Additionally, some use them in environmental projects, such as composting, where the drum acts as a vessel for converting organic waste into valuable compost. For industrial, environmental, or creative applications, 55-gallon drums are preferred for shipping and storing due to their durability, economic benefits, and standardization.

Different Types of 55-gallon Drums

As an industry standard for storage and transportation across various sectors, 55-gallon drums offer versatility and capacity for transporting oil, petroleum, pharmaceuticals, food, chemicals, and waste. The 55-gallon drums include steel, plastic, fiber, stainless steel, composite, and overpack drums. Each drum type is made up of a material most compatible with its intended use. For example, plastic closed-top drums are used for chemicals that react with metal, such as water, acid, and oxygen. Stainless steel drums are standard for storage and transportation in the food and beverage industry, where the purity of the content is a concern. When purchasing 55-gallon drums, several factors must be considered to ensure they match your specific storage and transportation needs. Checking the material, seal quality, and durability is crucial when considering the drums’ resilience to physical impacts.

Steel Drums

55-gallon steel drums are the most common type of drums suitable for storing oils, chemicals, and flammable materials. Open-top steel drums have a removable lid and are secured with a bolt ring or lever lock. This type of steel drum is commonly used for solids and thicker liquids. Closed-top steel drums, or tight-head steel drums, are typically used for liquids and have a non-removable lid with two bung holes or openings that can be tightly sealed.

Plastic Drums

Plastic drums, made from high-density polyethylene (HDPE), are resistant to many chemicals and often store acids, detergents, and other corrosive substances. 55-gallon plastic drums also come in open-top and closed-top drums. Open-top plastic drums are generally used for solids or viscous materials like steel drums. Closed-top plastic drums are standard for storing various chemicals, especially chemicals that might react with metal.

Fiber Drums

Fiber drums are composed of dense paperboard and are often used for storing dry products, powders, and less hazardous materials. These lightweight 55-gallon drums are commonly used for storing and shipping pharmaceuticals and food items.

Stainless Steel Drums

Similar to the design of regular steel drums, stainless steel drums are often used in food processing or pharmaceutical applications. Due to their non-reactive nature, stainless steel drums are often used in applications where content purity is crucial.

Composite Drums

Composite drums comprise a combination of materials, such as steel exterior with a plastic inner lining. These types of drums take advantage of the benefits of both materials.

Overpack Drums

Overpack 55-gallon drums are designed for storing and transporting smaller containers or damaged drums. These drums have a wider diameter than other drums to fit another drum inside. Although wider, overpack drums are still 55 gallons and come in polyethylene (plastic), steel, and composite material.

Safety Tips for Storing and Transporting Drums

Practicing safety measures when storing and transporting 55-gallon drums is crucial for accident prevention and ensuring the materials’ purity. Before storing your substances, always check that the material you’re holding is compatible with the drum material to prevent contamination or corrosion. Regularly inspect drum seals for any signs of damage, decay, or leaks. 55-gallon drums should be properly labeled with the contents inside, along with any related hazards. When transferring flammable materials, always ground the drums to prevent static electricity buildup, as this can cause explosions. All drums should be stored upright on a flat surface in a cool, dry place away from direct sunlight and extreme temperatures.

When transporting 55-gallon drums, secure drums to prevent tipping or spilling during transit. Ensure proper disposal methods, especially for drums that have contained hazardous materials. If reusing drums, they should be thoroughly cleaned and, if necessary, decontaminated to prevent cross-contamination. In areas where drums are stored and transported, fire extinguishers and personal protective equipment (PPE) should be present for safety protocol. Personal protective equipment, such as nitrile or vinyl gloves, protects the hands from harmful substances and sharp materials. By understanding the different types and uses of 55-gallon drums, you can maximize the benefits while ensuring safe and efficient operations in the workplace.

References:

- Rolling Barge. Seven Reasons Why 55 Gallon Drums Make Better Dock Floats.

- Home Crux, 2023. The Most Creative Ways to Reuse Oil Drums as Furniture.

Comments are closed.